|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GLASS

FUSING

-

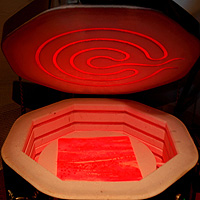

It is a particular thermic process which consists in bringing

a sheet of glass, put on a refractory plate inside a special kiln,

gradually to fusion temperature (about 800°C ), to bring it

slowly back to room temperature.

The kinds of glass used, Bullseye, Desag, Spectrum... are valuable

ones sold in sheets and especially studied for this kind of working

process.

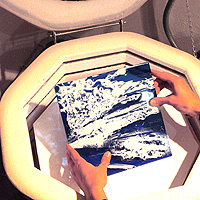

It is possible to put enamels, oxides, coloured powdered glass,

thin metal foils or wires, to obtain special effects in fusion.

The firing usually requires very long times to allow the molecules

to re-organize themselves in the passage through the solid state

to the viscose one, and back, avoiding to create tensions which

could even break the piece.

The complete heating and cooling cycle of the glass sheet lasts

from 8/12 hours and more, depending by the size, the thickness

and the esthetical results one wants to obtain.

To make objects with rather deep shapes it is necessary to carry

out two firings: one for the fusion and the other for shaping

glass over a mold. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|